Front loader

The main categories of sale are: agricultural machinery, rollers, loaders, agricultural, municipal, construction, forestry and farming equipment. We periodically enrich our assortment with newer and newer proposals.

Customer relationship

10/10

Reliability

10/10

Quality

10/10

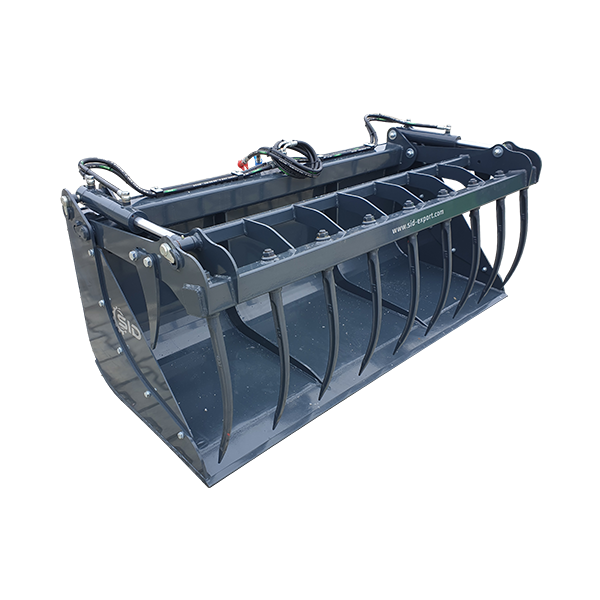

Front loader 1500

The 1500 front loader is mounted to tractor frames. It is used for the transport and loading of materials such as gravel, lime, fertilizer, manure. Additionally, thanks to them, it is possible to transport crops such as potatoes and beets. They can even be used when transporting trees. Front loaders work well mainly in agriculture, but more and more often they are used effectively in municipal industries.

Description

The 1500 front loader is available with a EURO or SMS tool change frame.

The 1500 front loader is an easy and safe work tool.

U – new type of arm profile

The plate of the outrigger arm is bent from one piece and stabilized with a transverse plate shifted to the inside. There are optically hidden hydraulic lines in the space created.

Concealed arrangement of hydraulic lines

![]()

Ease of detachment

Quick attachment and removal of the front loader has always been a strong point of this product.

Already in the standard version, the tractor and loader are hydraulically connected via four quick-connect couplings, which are color-coded, which prevents mistakes. The FASTER hydraulic coupler offers great comfort in operation. With one hand movement, the connection of four hydraulic connections and one electrical connection can be simultaneously activated or disconnected. The quick hitch is also available for quick connection of implements to the third hydraulic circuit. This reduces setup times and downtime. There are no significant leaks when attaching or detaching, so FASTER is also environmentally friendly. When the attachments are changed frequently, the double FASTER connection for attachments saves time and increases operating comfort.

![]()

Hydraulics

All hydraulics are protected against dirt and damage by a sturdy cover. An effective two-way pressure relief valve that responds at 210 bar protects the tool cylinders from overload during heavy loading work.

Vibration damping system

Thanks to the vibration damping system, annoying swaying of the tractor when transporting with the front loader mounted is almost completely eliminated. The 1500 front loader is amortized by long-lasting hydraulic accumulators. Thanks to the combination of hydraulic accumulators of lower and higher pressure, the effect of damping vibrations was obtained in a wider range of loads. In addition, the pressure in the damping system can be changed after calling the service, which will change the load range at which the vibrations are eliminated. A third hydraulic circuit for controlling hydraulically actuated attachments is standard equipment.

Intuitiveness

The 1500 front loader makes loading easier and more enjoyable. The loader stands securely on solid and reliable support feet. The locking and unlocking function is now improved, making it lighter and easier to use.

The tool setting indicator has been completely reworked. It is now more visible and intuitive to use.

Daily service has been made easier thanks to the exposure of all lubrication points on the outside of the loader.

![]()

Specification

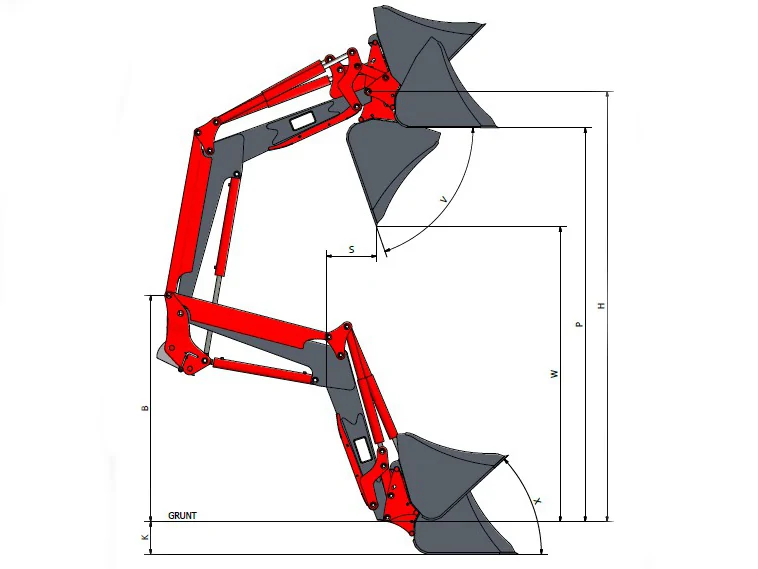

| Q1 | kg |

Lifting capacity on the EURO frame at the bottom (200bar) | 2357 |

| Q2 |

kg |

Lifting capacity on the EURO frame at the top (200bar) | 2147 |

| H |

mm |

Max lifting height at the tool pivot point | 3700 |

| P |

mm |

Loading height | 3450 |

| W |

mm |

Dump height | 2750 |

| S |

mm |

Dump width (variable depending on the tractor) | 750 |

| B |

mm |

The height of the boom on the tractor | 1847 |

| K |

mm |

Digging depth | 250 |

| V |

degrees | Dump angle | 70 |

| X |

degrees | The angle of the embankment | 43 |

| Q1 |

kg |

BOM weight |

480 + supporting structure |

The 1500 front loader is shot blasted and powder coated. This is by far the most effective of the modern metal coating methods used today. Contrary to traditional (liquid) varnishes, powder paints guarantee smooth coatings, without cracks, stains, bubbles and wrinkles. They are used for protective, anti-corrosion and decorative painting of metal objects. The thermal resistance of the coating is approx. 100 ° C. The coatings are characterized by very good mechanical properties and high resistance to chemical agents. A special advantage of powder paints is their versatility (thanks to the possibility of obtaining coatings with various degrees of gloss in a wide range of textures and structures, in full RAL colors).

Featured products in the category

Find out about the other products