Construction equipment

The main categories of sale are: agricultural machinery, rollers, loaders, agricultural, municipal, construction, forestry and farming equipment. We periodically enrich our assortment with newer and newer proposals.

Customer relationship

10/10

Reliability

10/10

Quality

10/10

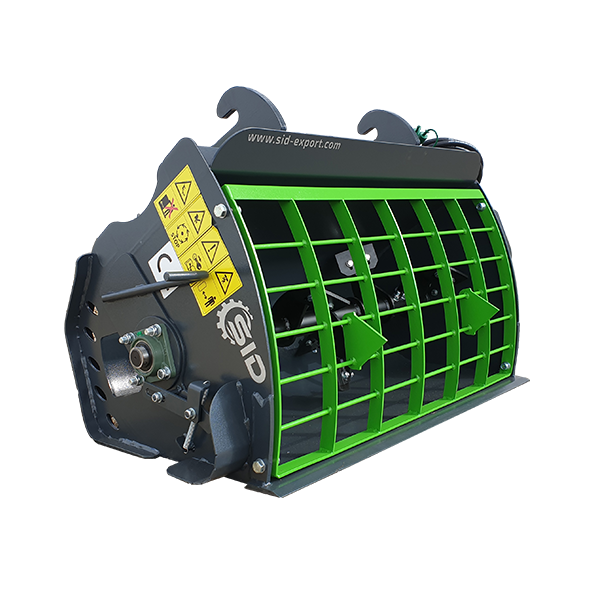

Screening bucket S/M

The screening bucket is used to screen bulk materials such as soil, aggregate, sand and compost without the need for shredding or crushing. The polyurethane stars mounted in the bucket rotate in the same direction, allowing the raw material to be separated. One direction of rotation of the rollers means that a unidirectional hydraulic line is required to drive the screening unit.

Description

Thanks to the soft material of the discs and their smooth movement, the spoon is gentle on materials such as peat or roots. The unit accurately separates the mixed material and does not get blocked by overflowing raw material that remains in the bucket.

Today, everyone appreciates a fast and efficient product . Our machine was built with the time-sensitive user in mind. It sifts material from the bucket in seconds and access to the drive and rollers is very quick and easy. If necessary, it does not take long to replace the stars. The attachment is very quiet during operation. The bucket has a robust and well thought-out design that will ensure comfortable, long-lasting and safe handling.

Match the bucket to your equipment! The screening bucket can be fitted to excavators, tractors, telehandlers, skid steer loaders, wheel or track loaders and mini-loaders, replacing the standard digging bucket.

The spoon is used for sifting materials such as:

- stone

- ground

- gypsum

- sand

- fertiliser

- separation of mixed waste

- stone waste

- fine screening

- screening of green waste

- sifting of rubbish

Main product features

A solid and durable structure made of high-strength steel S355.

Geretor engine.

Solid c45 shafts.

Blade Hardox.

Generator motor.

A system of specially designed polyurethane stars ensures excellent service life and maximum performance of the screening bucket.

Protective covers for the drives.

Built-in motor protected from damage.

Hardened rim gears - Reinforced chain.

Specification

| Width | Volume |

Type of stars |

Nr of shafts |

Nr of shafts |

Weight |

Weight of excavators |

| 650 mm | 0,05 m³ | 160 mm |

35 pc. |

2 pc. |

110 kg |

1-2 T |

| 850 mm | 0,10 m³ | 160 mm | 53 pc. | 3 pc. | 164 kg | 2-4 T |

| 850 mm |

0,13 m³ |

160 mm |

71 pc. |

3 pc. |

190 kg |

3-5 T |

| 1050 mm |

0,16 m³ |

160 mm |

89 pc. |

3 pc. |

220 kg |

4-6 T |

Screening bucket is a construction equipment that is shot blasted and powder coated. This is by far the most effective of the modern metal coating methods used today. Contrary to traditional (liquid) varnishes, powder paints guarantee smooth coatings, without cracks, stains, bubbles and wrinkles. They are used for protective, anti-corrosion and decorative painting of metal objects. The thermal resistance of the coating is approx. 100 ° C. The coatings are characterized by very good mechanical properties and high resistance to chemical agents. A special advantage of powder paints is their versatility (thanks to the possibility of obtaining coatings with various degrees of gloss in a wide range of textures and structures, in full RAL colors).

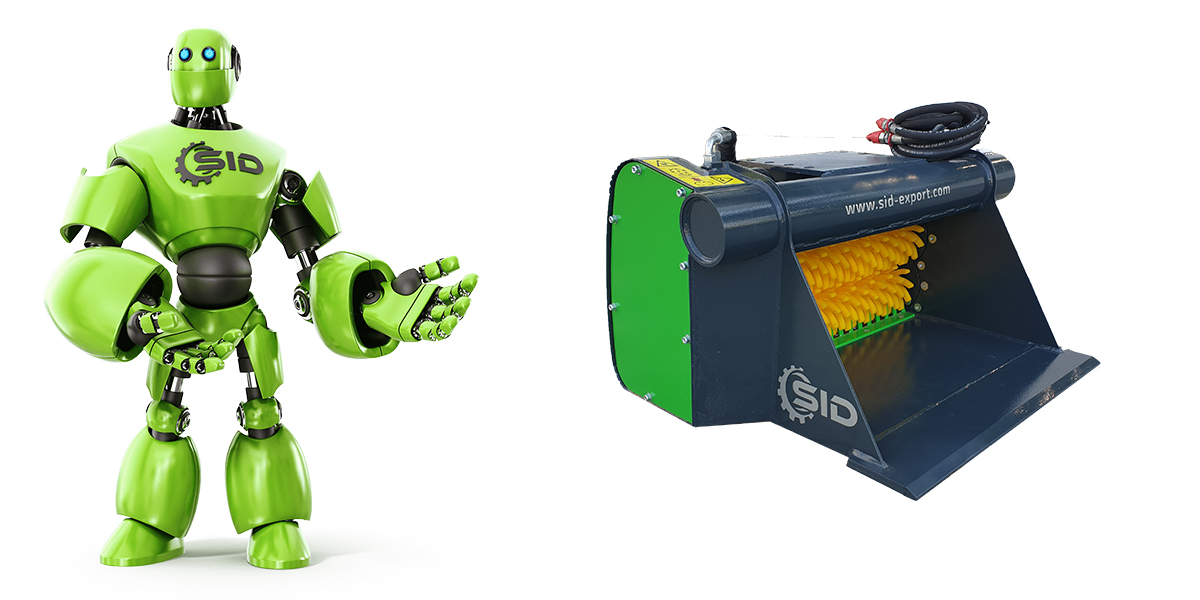

As part of our policy of continuous improvement, SID company may introduce changes to the technical specifications without prior notice. Information and graphics on our website are provided for informational purposes only. Certain equipment elements may be available as an option and are not part of the standard offer. To learn more about the warranty, safety standards, and products, please contact a SID company representative.

Presentation of machines at work

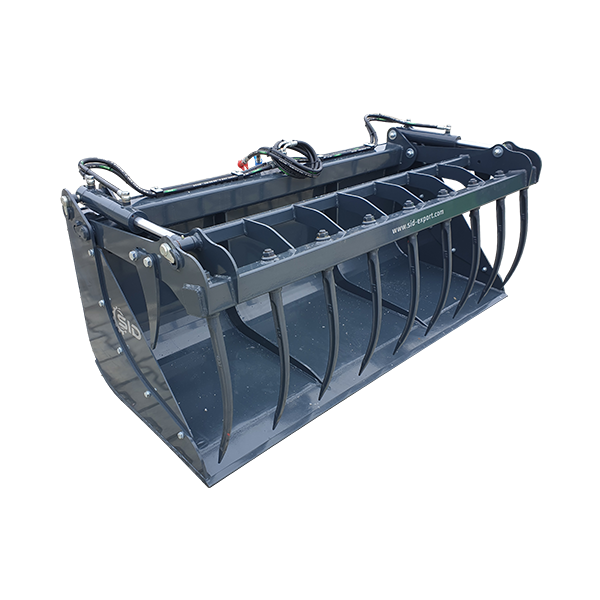

Featured products in the category

Find out about the other products