Construction equipment

The main categories of sale are: agricultural machinery, rollers, loaders, agricultural, municipal, construction, forestry and farming equipment. We periodically enrich our assortment with newer and newer proposals.

Customer relationship

10/10

Reliability

10/10

Quality

10/10

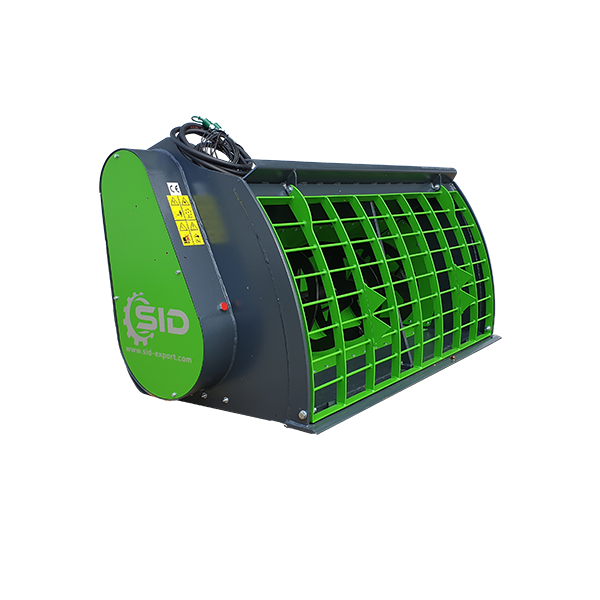

Side discharge bucket

Description

Main product features

Supporting the small rack in the gearbox with bearings - removing the load on the hydraulic motor.

The option to change components to those resistant to high temperatures, which allow for work with hot materials such as asphalt.

The lower part with a blade has been moved forward in the mixer for easier scooping of gravel straight from the heap.

The Tornado concrete mixer is made of S355 steel with a thickness of 6mm with replaceable 3mm thick inserts, screwed to the mixer structure in places exposed to abrasion.

12-month warranty.

Driven by the 800 cm3 OMT orbital hydraulic motor.

Power transmission through the chain 20b1.

Easy access to chain lubrication.

Self-aligning bearings with the possibility of lubrication.

Additional leakage of leaks ahead of the bearings.

Additional bearing seals.

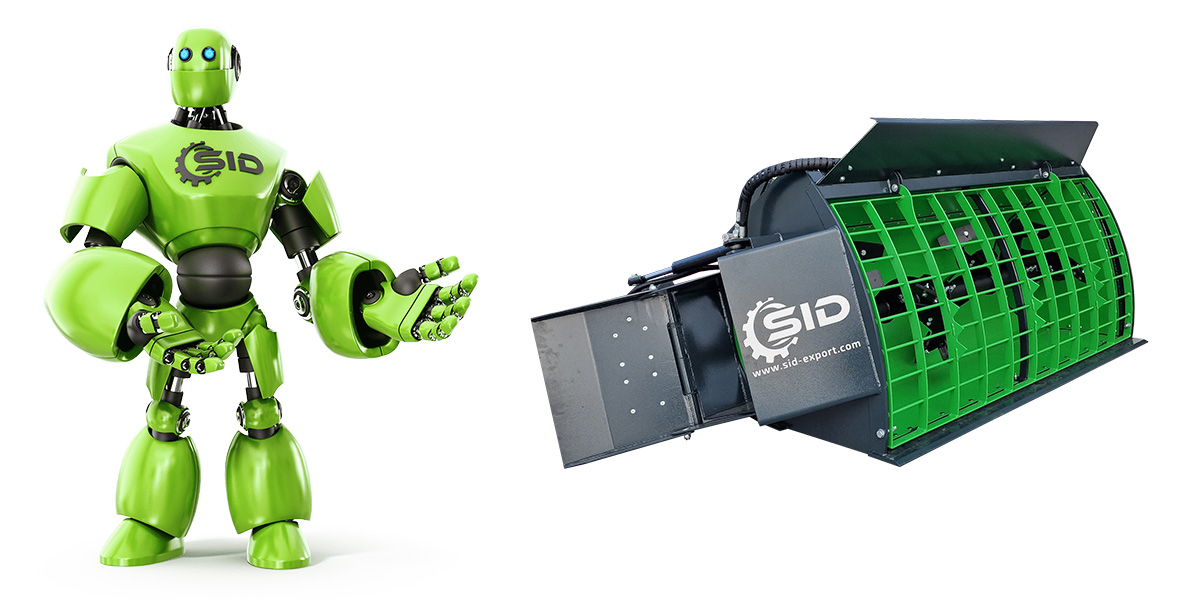

Additional option

Hydraulically opening front hatch.

Hydraulic shock absorbers for two engines.

Hardox liner.

Specification

| Width | Capacity | Weight |

| 1500 mm |

0,60 m³ | 845 kg |

| 1750 mm |

0,80 m³ | 908 kg |

| 2000 mm |

1,00 m³ | 972 kg |

| 2200 mm |

1,20 m³ | 1070 kg |

The side discharge bucket we offer is sandblasted and powder coated. This is by far the most effective of the modern metal coating methods used today. Contrary to traditional (liquid) varnishes, powder paints guarantee smooth coatings, without cracks, stains, bubbles and wrinkles. It is used in protective, anti-corrosion and decorative painting of metal objects. The thermal resistance of the coating is approx. 100 ° C. The coatings are characterized by very good mechanical properties and high resistance to chemical agents. A special advantage of powder paints is their versatility (thanks to the possibility of obtaining coatings with various degrees of gloss in a wide range of textures and structures, in full RAL colors).

As part of our policy of continuous improvement, SID may make changes to the technical specifications without prior notice. Information and graphics on our website are for informational purposes only. Certain equipment features may be available as an option and are not part of the standard offer. To learn more about the warranty, safety standards, and products, please contact a SID representative.

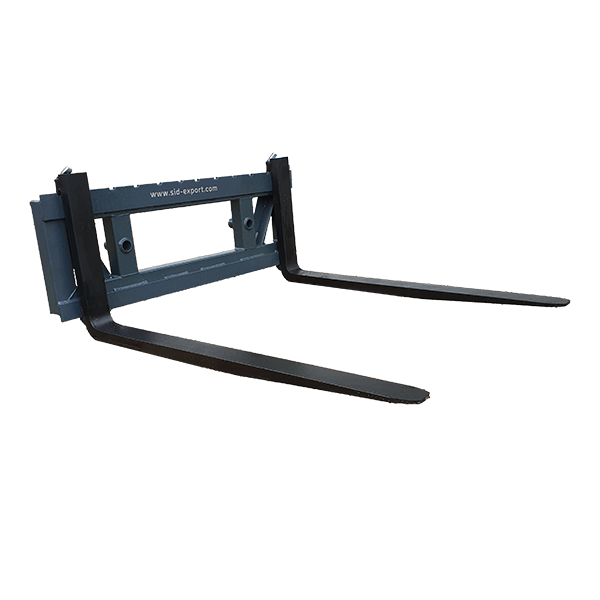

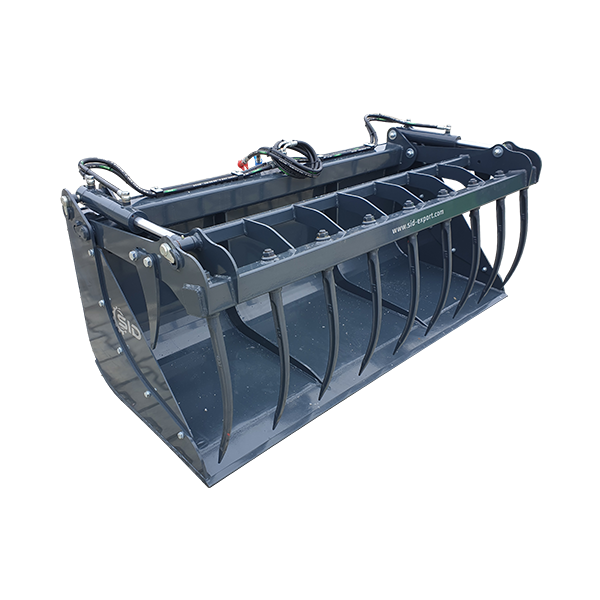

Featured products in the category

Find out about the other products