Agricultural equipment

The main categories of sale are: agricultural machinery, rollers, loaders, agricultural, municipal, construction, forestry and farming equipment. We periodically enrich our assortment with newer and newer proposals.

Customer relationship

10/10

Reliability

10/10

Quality

10/10

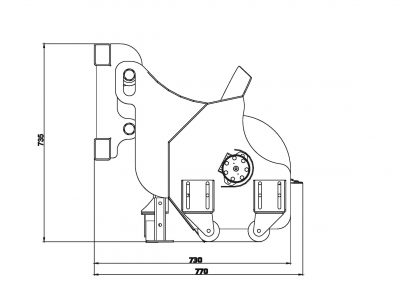

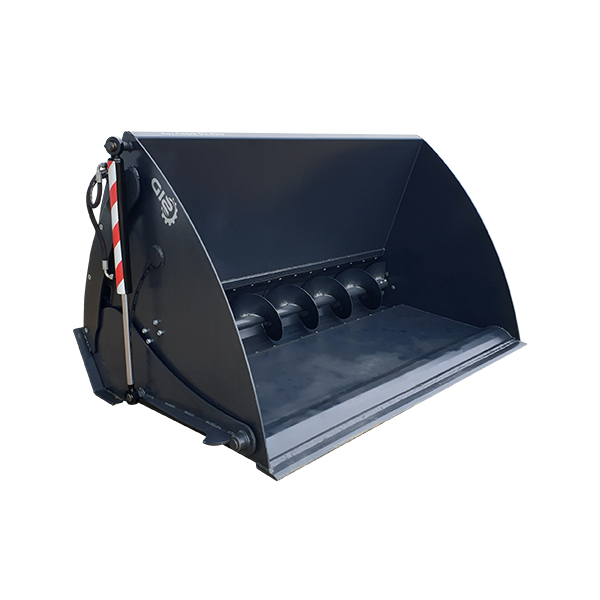

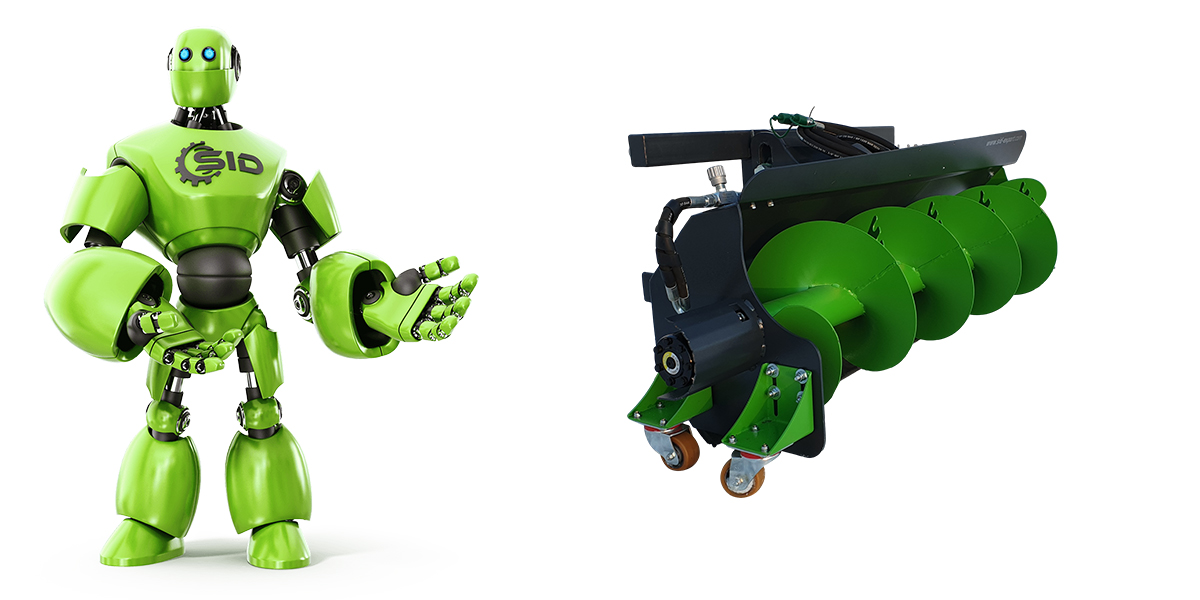

TMR Feed Pusher

The TMR feed pusher is an agricultural device used for transferring, distributing, and moving feed on feed tables in barns or other locations where animals are fed. It is particularly useful in cattle breeding, where regular and even distribution of feed is crucial for the health and productivity of the animals. The TMR feed pusher features a helical scraping mechanism that is moved along the feed table, pushing the feed closer to the animals. This helps prevent feed wastage and ensures that animals have easier access to nutritious food.

Description

Main product features

Screw thickness – 3 mm.

Plate thickness – 6 mm.

Screw diameter – 410 mm.

Hydraulic engine.

Rubber blade.

Screw-on mounting type WD.

Floating frame.

Oil flow controller.

Safety valve - cross valve.

A quick and easy way to provide animal feed.

Refreshing and mixing the feed on the feed fence.

Better quality and no overheating of the feed.

Easily and quickly increases the feed intake of the animals.

Specifications

| Width | Weight |

| 1000 mm |

110 kg |

| 1200 mm |

130 kg |

| 1400 mm |

150 kg |

| 1600 mm |

170 kg |

| 1800 mm |

190 kg |

| 2000 mm |

210 kg |

| 2200 mm |

230 kg |

| 2400 mm |

250 kg |

TMR Forage pusher is an agricultural equipment that is shot blasted and powder coated. This is by far the most effective of the modern metal coating methods used today. Contrary to traditional (liquid) varnishes, powder paints guarantee smooth coatings, without cracks, stains, bubbles and wrinkles. They are used for protective, anti-corrosion and decorative painting of metal objects. The thermal resistance of the coating is approx. 100 ° C. The coatings are characterized by very good mechanical properties and high resistance to chemical agents. A special advantage of powder paints is their versatility (thanks to the possibility of obtaining coatings with various degrees of gloss in a wide range of textures and structures, in full RAL colors).

As part of our policy of continuous improvement, SID company may introduce changes to the technical specifications without prior notice. Information and graphics on our website are provided for informational purposes only. Certain equipment elements may be available as an option and are not part of the standard offer. To learn more about the warranty, safety standards, and products, please contact a SID company representative.

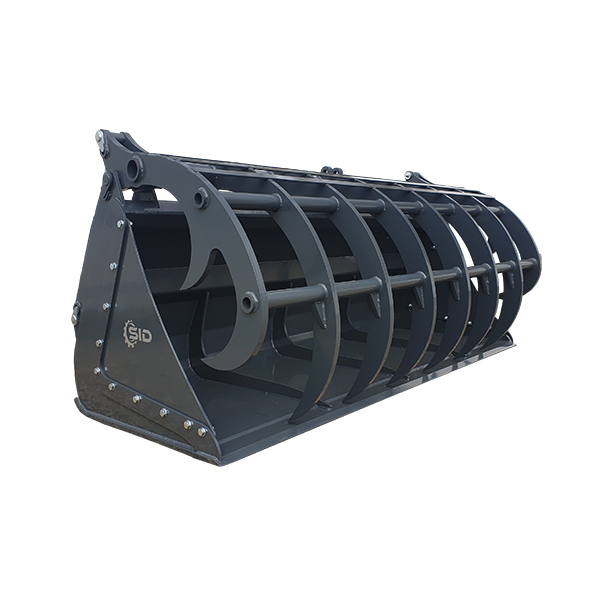

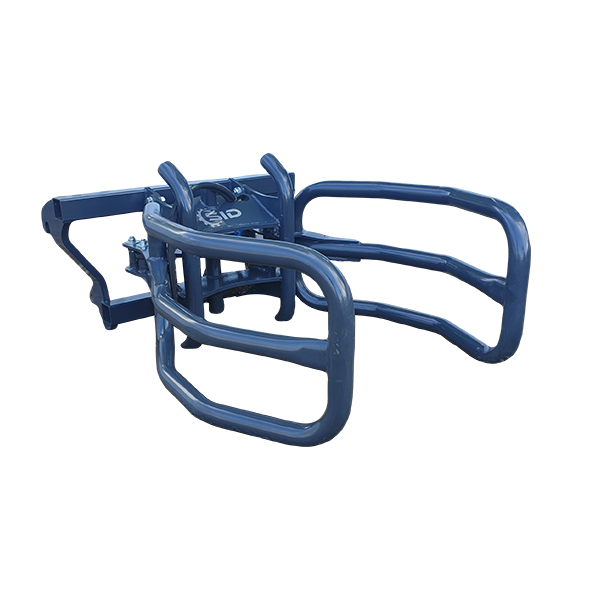

Featured products in the category

Find out about the other products